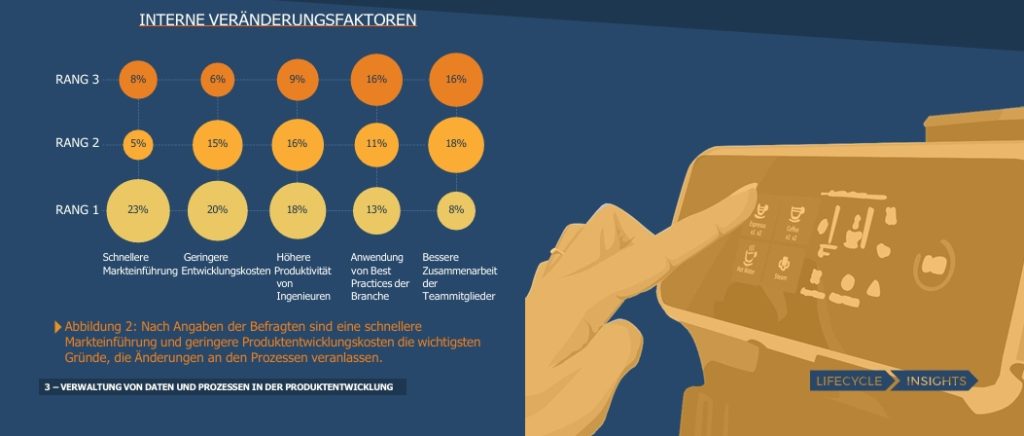

In today’s fast-paced market, manufacturing companies face growing pressure to innovate and accelerate time to market. The 2022 PDM/PLM Study from Lifecycle Insights reveals key internal factors driving companies to rethink how they manage product development data and processes to stay competitive.

Why Companies Are Adopting PDM/PLM Solutions

According to survey respondents, the primary drivers for change are faster time to market (23%) and reducing product development costs (20%). However, a broader range of motivations emerged, with 40% or more of respondents identifying the following top factors for change:

- Higher Productivity for Engineers and Teams (43%)

- Improved Collaboration across Departments (42%)

- Cost Reductions in Development (41%)

- Adoption of Industry Best Practices (40%)

- Accelerated Time to Market (36%)

These insights show that manufacturing companies are increasingly adopting Product Data Management (PDM) and Product Lifecycle Management (PLM) solutions to enhance process efficiency, collaboration, and product competitiveness.

Streamline Manufacturing for Success

Just as in product development, managing manufacturing data through conventional tools such as email can risk costly delays and missed deadlines. Design changes, specification updates, or other critical information can easily get lost, overlooked, or miscommunicated, impacting production schedules and launch dates.

PDM/PLM solutions solve these challenges by unifying product data in a single digital thread, enabling real-time updates and access for all stakeholders—whether they’re engineers, suppliers, or project managers. With PDM/PLM solutions, your team can coordinate efficiently, quickly adapt to changes, and consistently bring products to market faster.

Key Findings from the PDM/PLM Study

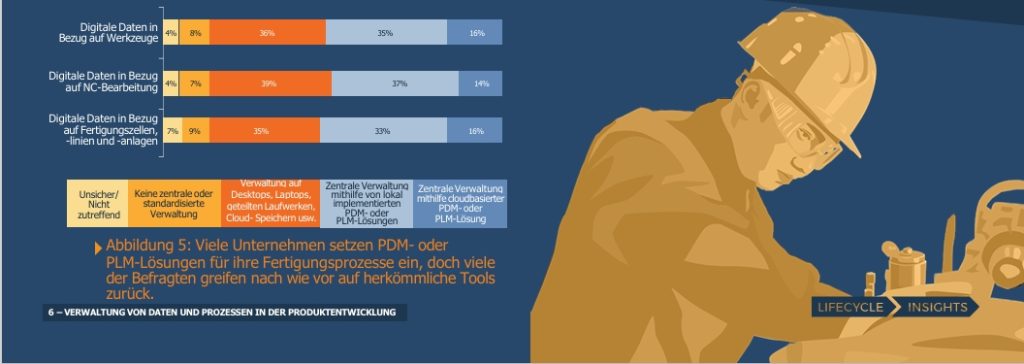

The study shows that many companies are already embracing PDM/PLM for manufacturing processes, using these solutions to:

- Communicate data with internal manufacturing teams and external suppliers (45%)

- Support prototyping and testing efforts (55%)

- Plan tools, equipment, and resources (50%)

However, the study also highlights a gap—over half of manufacturers still rely on traditional office tools, which may limit their ability to streamline processes:

- 51% use office tools to communicate with manufacturing and suppliers

- 42% rely on them for prototyping and testing

- 46% use them to manage tools and equipment

Transform Your Product Development and Manufacturing with PDM/PLM

Lifecycle Insights’ 2022 study provides valuable insights into the benefits of PDM/PLM solutions for managing product development and manufacturing processes. Embrace the power of digital tools to enhance collaboration, streamline data management, and reduce time to market. Discover how PDM/PLM can transform your manufacturing operations and help you stay ahead in an increasingly competitive industry.

This article is posted at autodesk.com

Please fill out the form to access the content